Imagine friction at the doctor blade or smouldering particles from your Yankee Dryer. These can create glowing hot spots in the tissue web that are rapidly reeled onto the mother roll. Unsuspected, you transport the contaminated roll to the warehouse and though it can take hours or even days, finally the contaminated mother roll bursts into flames and suddenly a minor problem at the doctor blade has become a major problem in your warehouse!

Imagine friction at the doctor blade or smouldering particles from your Yankee Dryer. These can create glowing hot spots in the tissue web that are rapidly reeled onto the mother roll. Unsuspected, you transport the contaminated roll to the warehouse and though it can take hours or even days, finally the contaminated mother roll bursts into flames and suddenly a minor problem at the doctor blade has become a major problem in your warehouse!

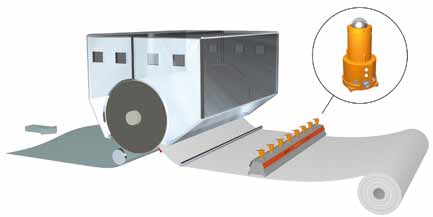

To prevent fire in stored tissue rolls, Firefly has developed the WebScan™ system, consisting of several detectors mounted above the web between the Yankee dryer and Reel-up. Heat radiation emitted by dangerous ignition sources on the web are detected and, within milliseconds of finding a hot spot, an alarm is indicated by the Firefly control unit. The alarm enables operators to remove the contaminated roll to a safe quarantine area for further inspection and disposal or re-pulping.

The WebScan™ (WD) detectors used in the system are specially designed for the tissue industry. A Firefly WD detector indicates hot spots, glows and sparks above 250°C on the tissue web. As each detector in the system is individually addressed, the system can help identify the location of the hot spot along the width of the roll. As some tissue machines are quite hot at the dry end and wash downs are common, the WD detectors utilise Firefly Self Diagnostics (FSD technology) to confirm sensitivity, internal temperature and humidity.

Standard at SCA Tissue

Standard at SCA Tissue

In 2005, SCA standardised on Firefly WebScan™ fire prevention technology in all its European tissue plants. SCA based their decision on the strong focus and persistent belief in loss prevention, as this safeguards the health of employees, the security of its plants and enhances the bottom line. Since then an increasing number of other tissue plants worldwide have followed SCA and realised the value of investing in fire prevention solutions.

Back to Tissue Production Solutions